Foam Dispensers

Provide metered, repeatable dispense cycles engineered to stabilize user delivery and reduce aggregate consumable demand relative to bulk liquid dispensing. Lower soap mass-per-use can extend replenishment intervals, improve custodial route density planning, and reduce drip-related hazards at lavatory deck surfaces and adjacent floor finish assemblies in contemporary restroom environments.

Foam soap dispensers are specified in commercial washrooms for quantifiable operations drivers: controlled dosing, reduced consumable loading, improved sink deck cleanliness, and longer service intervals under high occupant throughput. This guide outlines foam system mechanics, specification criteria, and field validation steps to confirm performance after installation.

Why foam dispensers are often a better commercial choice than bulk liquid

Controlled output improves predictable hand hygiene

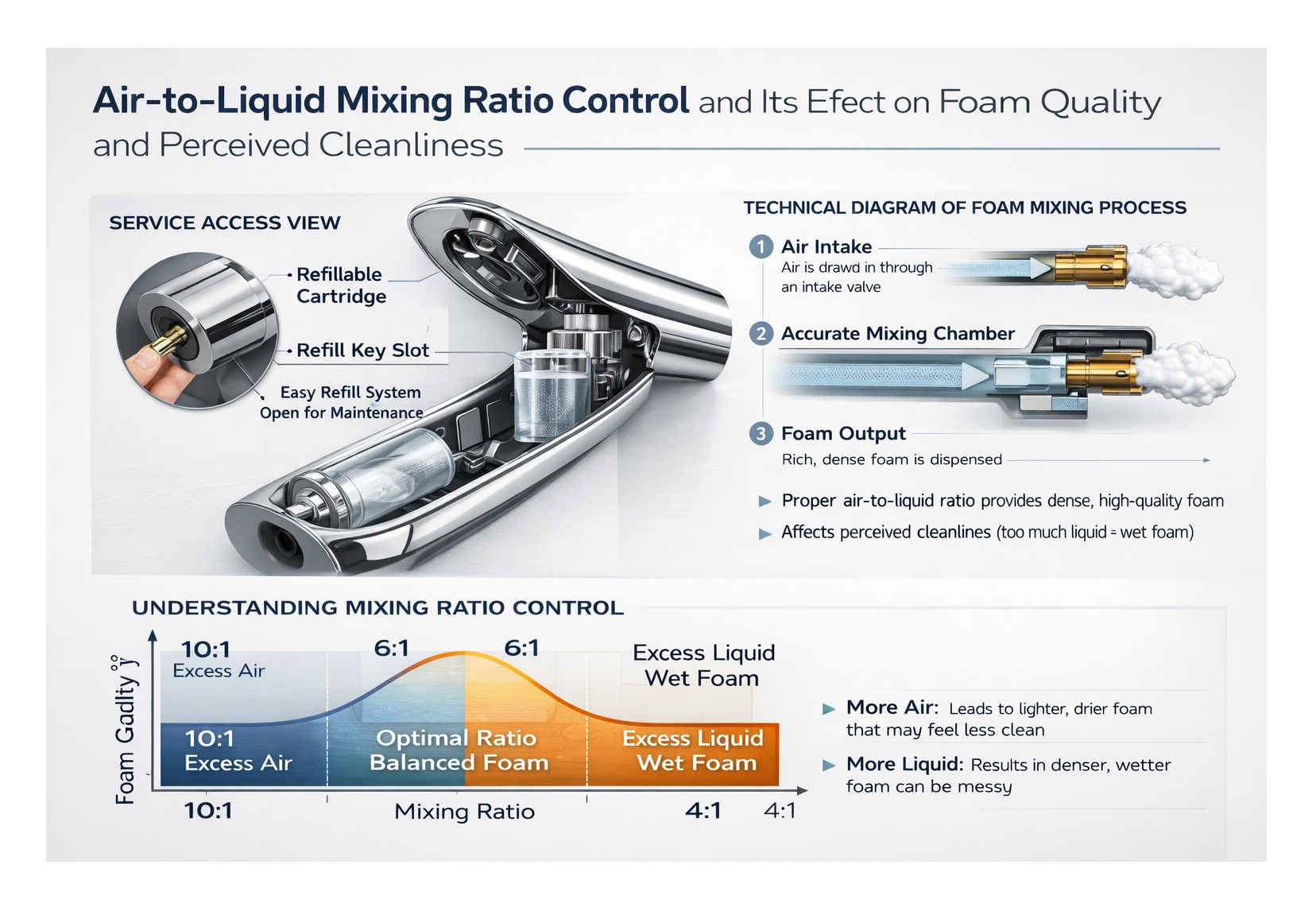

Conventional bulk liquid dispensers frequently exhibit dose variability driven by user pump cadence, product viscosity drift, and inconsistent refill practices. Foam systems reduce that dispersion because unit output is governed by a defined dispense cycle and controlled air-to-liquid mixing within the dispenser body. Repeatable, engineered dosing supports consistent user completion behavior by removing a primary variable in the wash sequence.

Lower product consumption with usable coverage

Foam output is delivered as an aerated matrix rather than a high-mass liquid slug. End users typically perceive higher volume and easier spread while consuming less soap concentrate per cycle. For design and operations teams, the technical driver is the controlled entrainment of air into the soap concentrate, which changes apparent volume, contact distribution, and user rub dynamics without requiring higher chemical loading.

Reduced mess at the lavatory deck helps safety and finish protection

Bulk liquid dispensing can introduce stringing, after-drip, and pooling that accumulates on deck planes and at backsplash seams. Foam systems generally reduce drip loading because the dispensed medium has lower free-flow behavior and improved nozzle stability, particularly when paired with effective check-valve architecture and anti-drip outlet geometry.

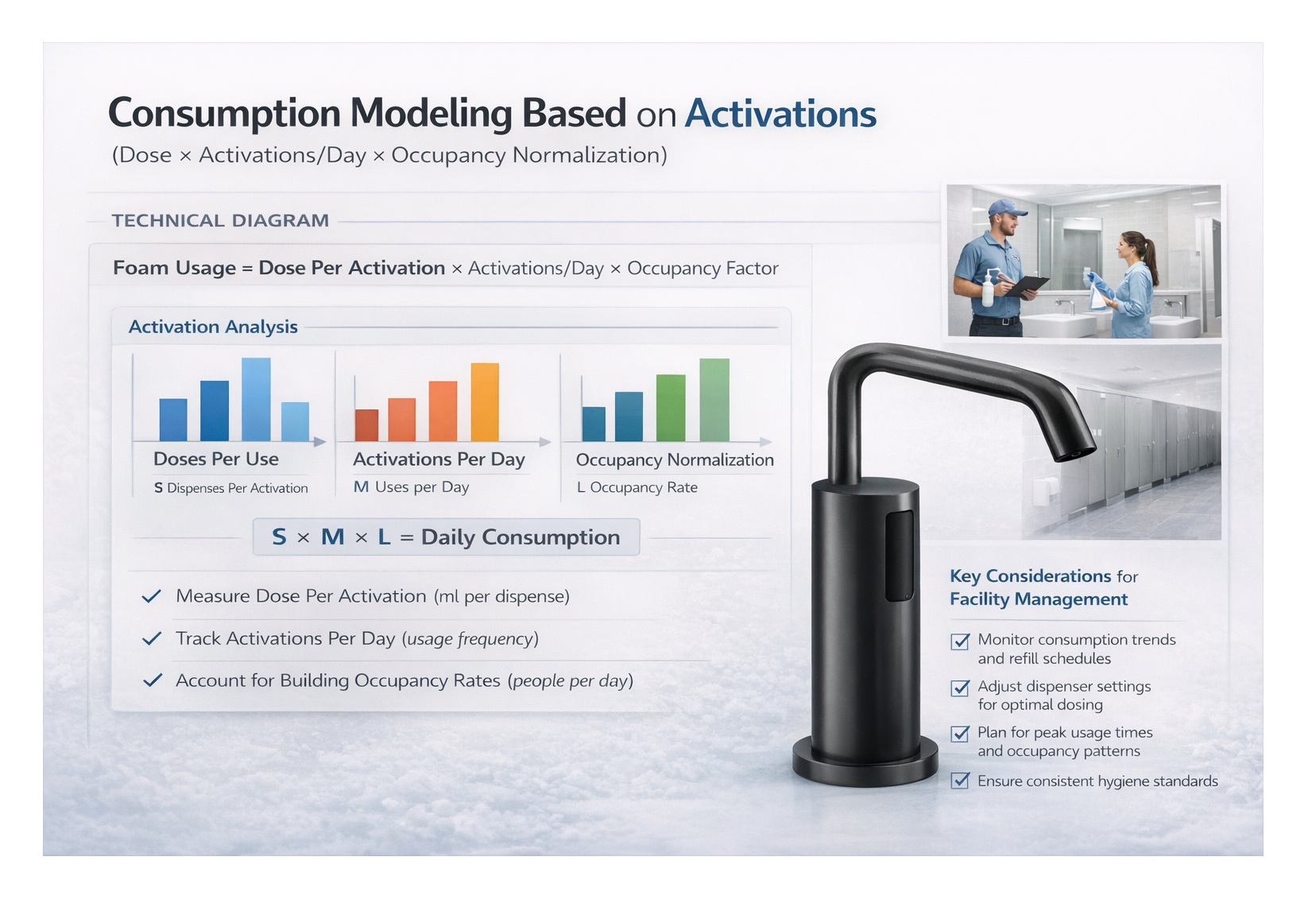

Longer service intervals and better route optimization

Reduced mass-per-wash directly extends refill and replacement intervals, improving service predictability at portfolio scale. In multi-site programs, small per-cycle savings can materially affect stocking rates, cart loading, and custodial route sequencing when modeled across daily traffic volumes.

How foam dispensers work

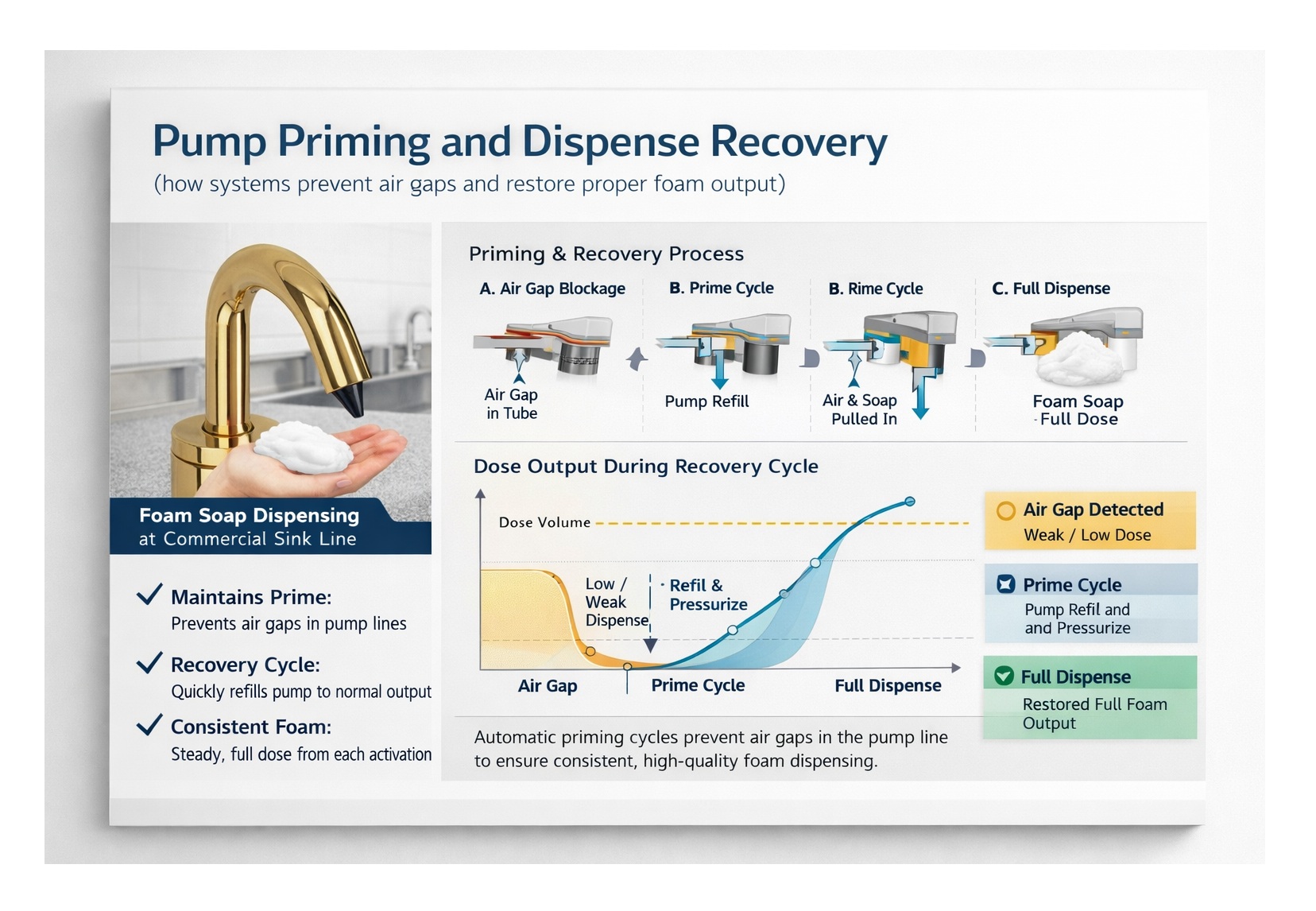

A foam dispenser generates a stable foam charge by coordinating metered liquid delivery, controlled air induction, and outlet valve behavior. It is not a direct analogue to liquid pumping. The system intentionally forms foam via entrained air and controlled bubble formation characteristics to produce a consistent texture and spread profile at the point of use.

Metered pump output

Air mixing or foaming element

Valves and anti-drip behavior

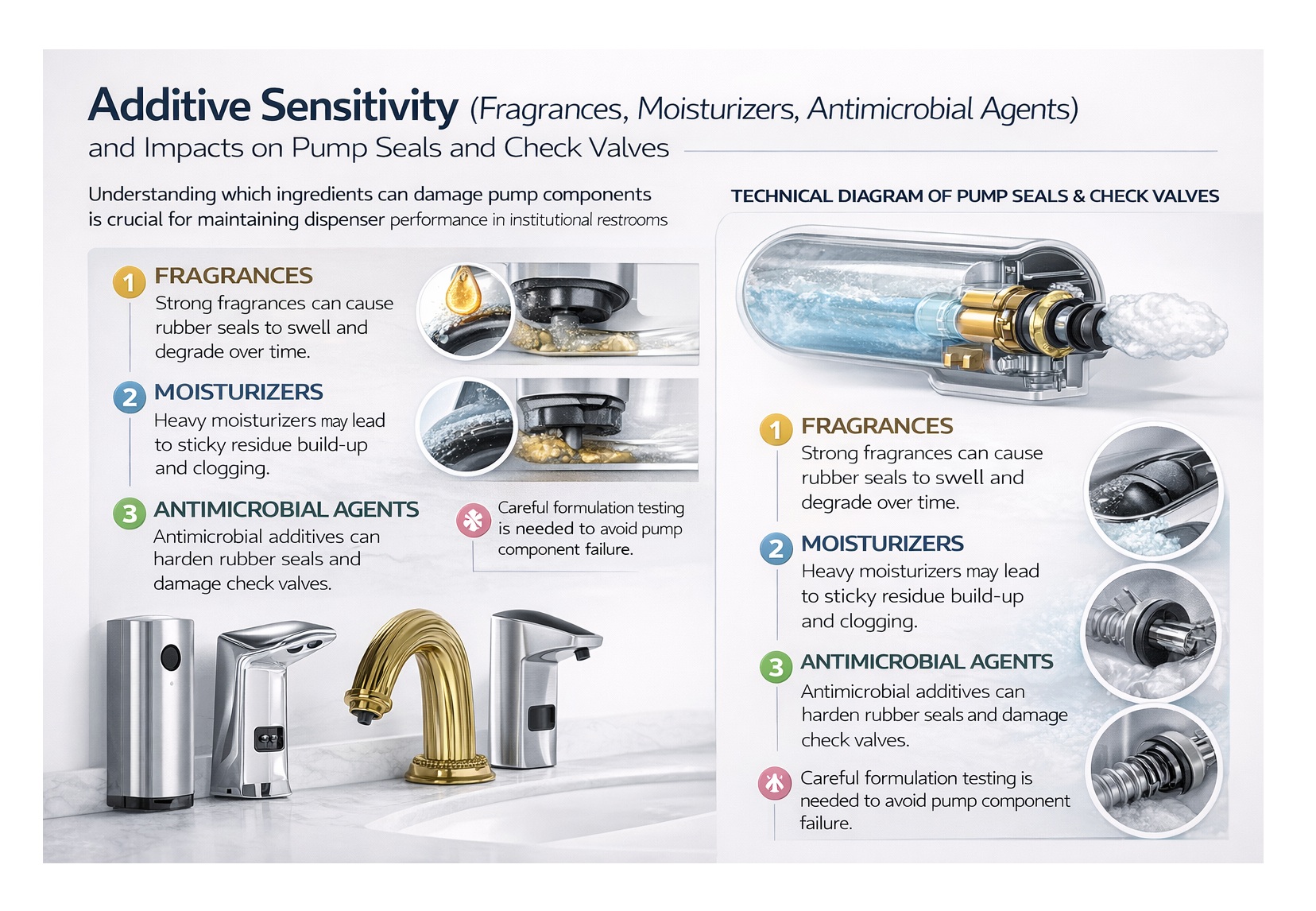

Commercial-grade units commonly incorporate check valves, controlled outlet restrictions, and nozzle sealing strategies to reduce after-drip and stringing. Anti-drip performance should be treated as a legitimate specification parameter because it directly impacts housekeeping workload, floor safety exposure, and finish maintenance cycles across the facility lifecycle.

Foam dosing, realistic volumes, and hygiene efficacy

Field-representative dosing volumes are frequently lower than historical assumptions used in older handwash validation models. A randomized controlled trial published in the American Journal of Infection Control evaluated foaming handwashes at realistic dispense volumes (0.9 mL and 2.0 mL) and reported that both products achieved FDA success criteria using a healthcare personnel handwash method under controlled conditions.

Practical takeaway for project teams: validated efficacy at realistic metered volumes supports foam dispenser dosing models when formulation, mixing, and user process alignment are correct.

What to specify for commercial foam dispensers

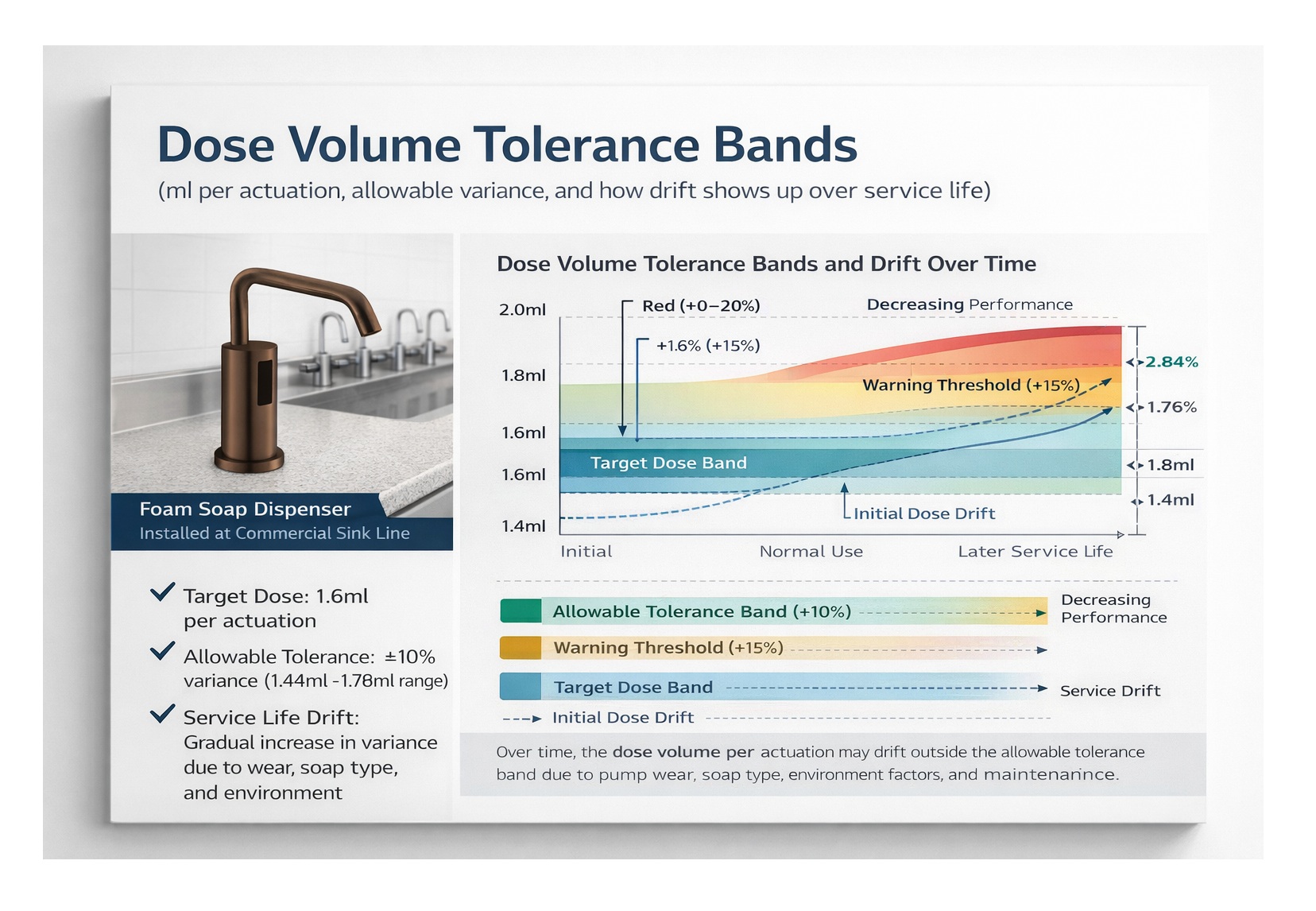

Dispense consistency

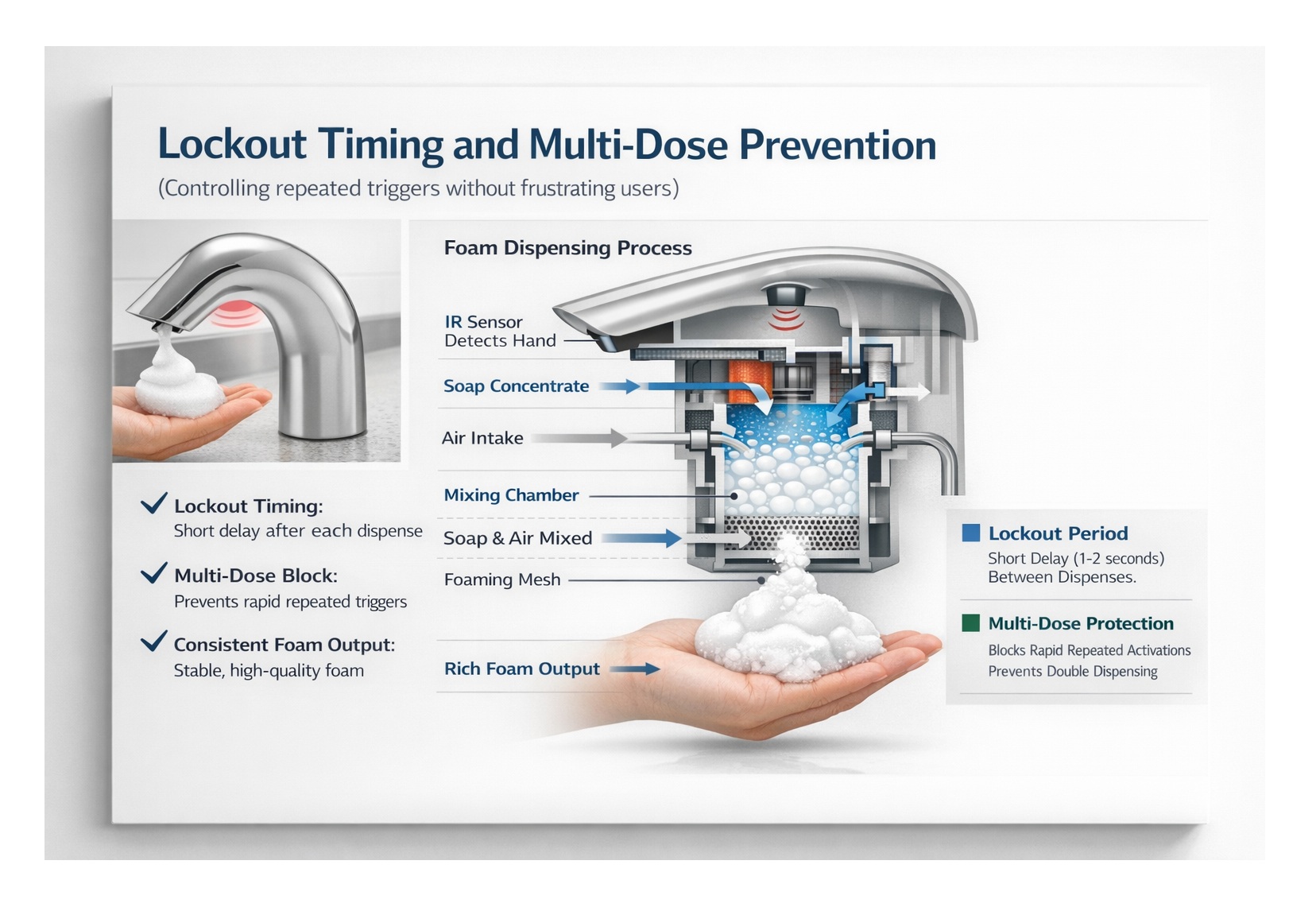

Sensor activation reliability and lockout timing

Refill system strategy: sealed refills vs bulk foam

Sealed cartridge refills are often preferred in controlled environments because they reduce formulation variability and simplify servicing workflows. Bulk fill approaches may lower consumable cost, but they introduce higher variability risk and require stronger housekeeping discipline to prevent mismatched products, dilution errors, and inconsistent performance outcomes.

Serviceability and visual refill monitoring

Finish durability and vandal resistance

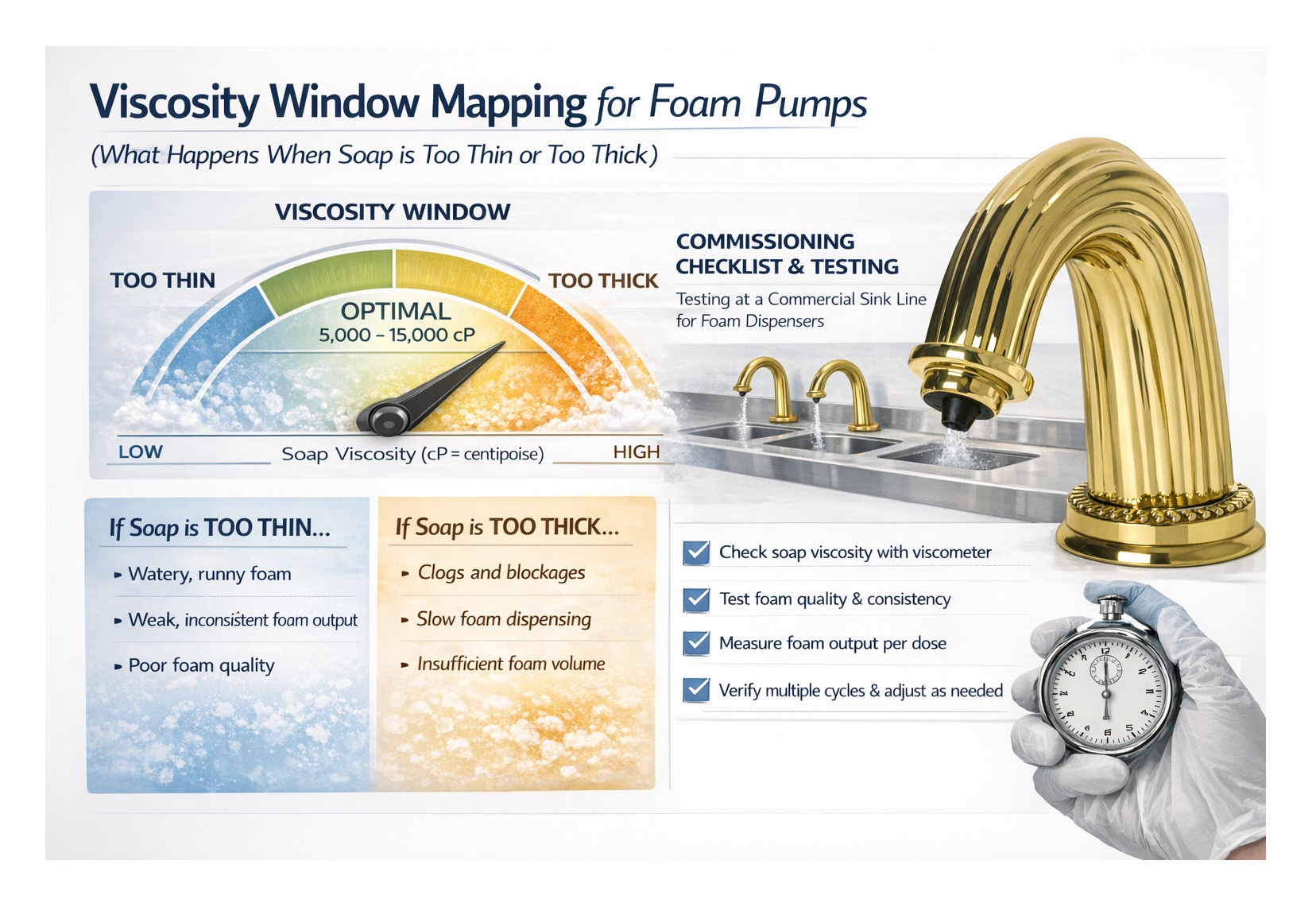

Commissioning and field performance checks

Field checks worth including in commissioning

When the dispenser is installed as part of a touchless suite, validate the full wash sequence as an integrated workflow: sensor faucet wetting → foam dispense → scrub → rinse → dry.

Recommended brands for commercial infrared sensor foam dispensers

The following options are widely deployed in institutional and high-throughput restrooms and typically provide mature service ecosystems, replacement-part continuity, and standardized refill programs suitable for long-term facility operations.

Spec language checklist

Foam soap dispenser shall:

Why foam dispensers align with modern operations and risk mitigation plans

Foam dispensers provide metered, repeatable dispense behavior that improves user interaction consistency and reduces consumable loading compared to bulk liquid systems. Lower product mass-per-use supports extended service intervals, improves custodial route planning, and reduces drip-related slip exposure at lavatory deck surfaces and adjacent floor finish zones.

From an AEC delivery standpoint, the optimal foam dispenser is the unit that maintains stable performance under real installed conditions: reflective finishes, high occupant throughput, aggressive cleaning regimens, and variation in user behavior. When specified and commissioned correctly, foam dispensers function as a predictable, low-maintenance subsystem within the broader hygiene program, reducing operational friction across the facility lifecycle.

No responses yet