Spray or Mist Units

Provide ultra-low volume, rapid application suited to high turnover areas and compact handwash zones. Fine atomization reduces residue buildup, supports cleaner counter detailing, and can help maintain fixture appearance while limiting replenishment frequency in distributed facilities for modern spaces.

Spray or mist units deliver soap or sanitizer-formulated solutions as a fine atomized spray rather than foam or bulk liquid. In high-turnover environments, this can reduce residue at basin decks, keep fixture detailing cleaner, and extend replenishment intervals due to extremely low dose volumes.

What spray or mist units are and why they exist

A spray or mist unit dispenses soap or hand hygiene solution as an atomized plume. Instead of pushing product into the hand as a cohesive volume, it delivers a thin, evenly distributed film across the user’s palm.

Why spray and mist units can be useful in modern commercial restrooms

Faster user cycle in high turnover spaces

In restrooms with short dwell time and constant flow, the handwashing process needs to be frictionless. A spray dose is often delivered in a short burst, supporting fast-moving circulation environments.

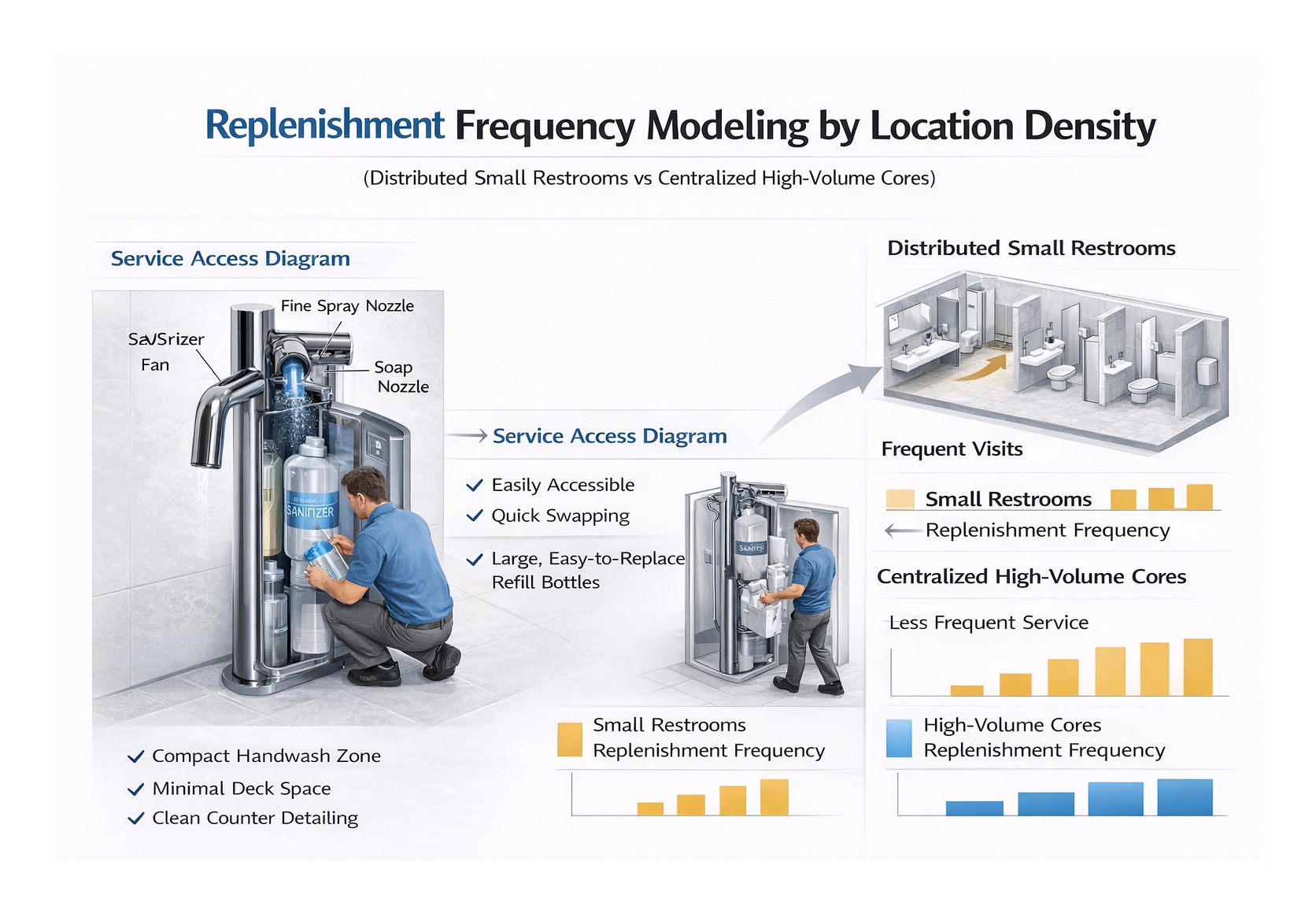

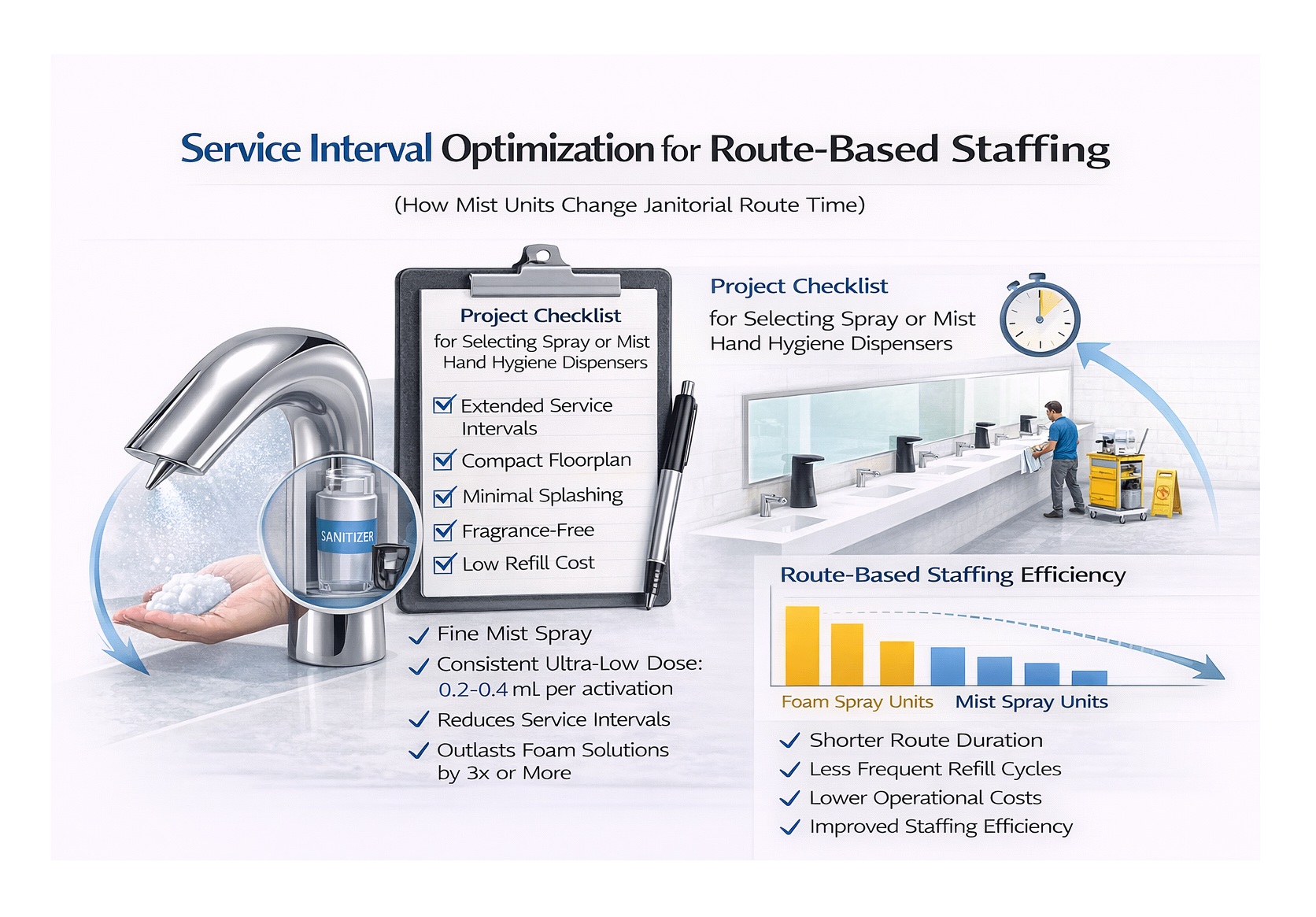

Ultra-low volume can reduce replenishment frequency

Because mist dosing can be very low per activation, replenishment frequency can drop in distributed buildings. This can reduce refill labor visits, stock movement across sites, and emergency empty-unit calls.

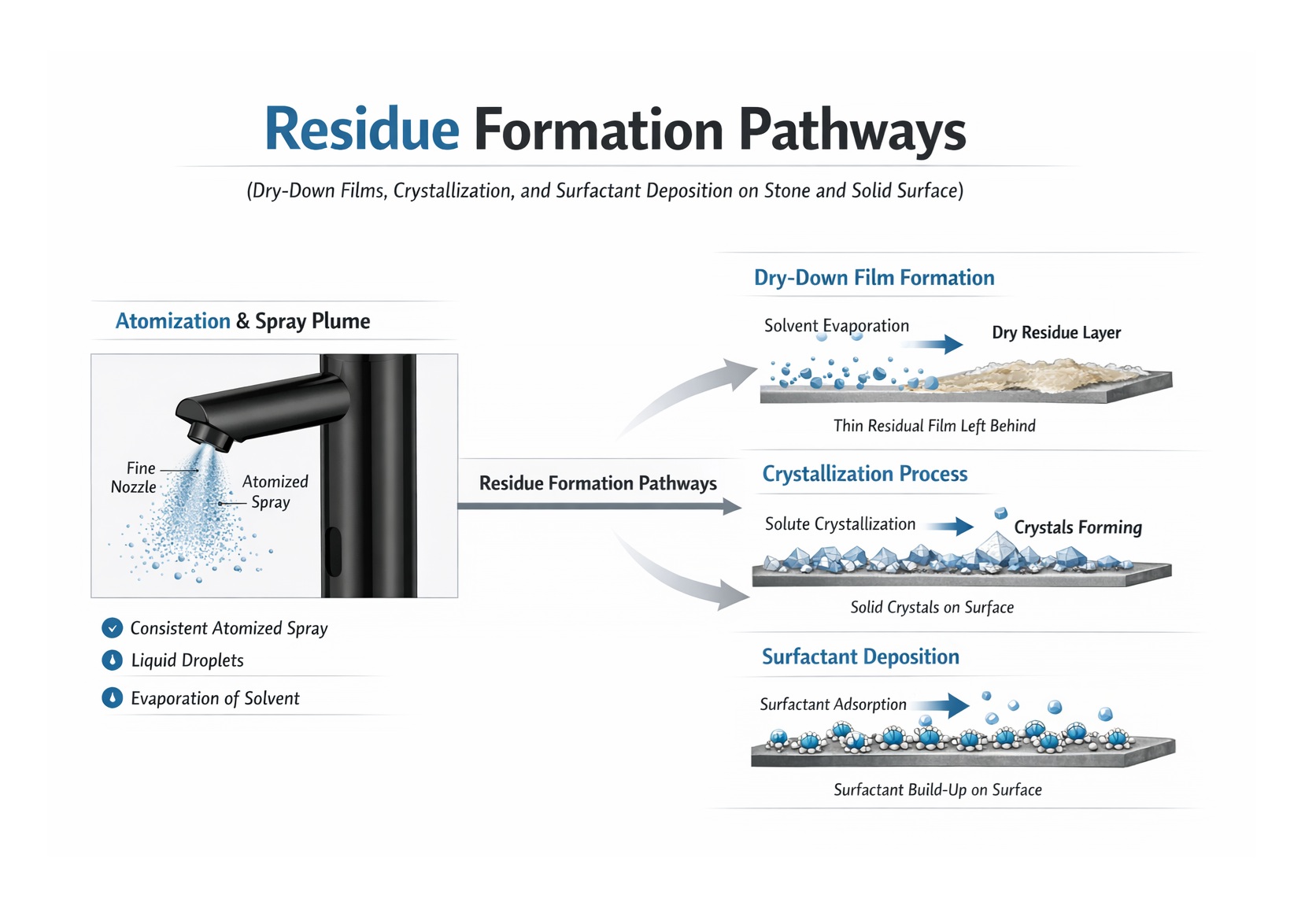

Fine atomization can reduce residue buildup

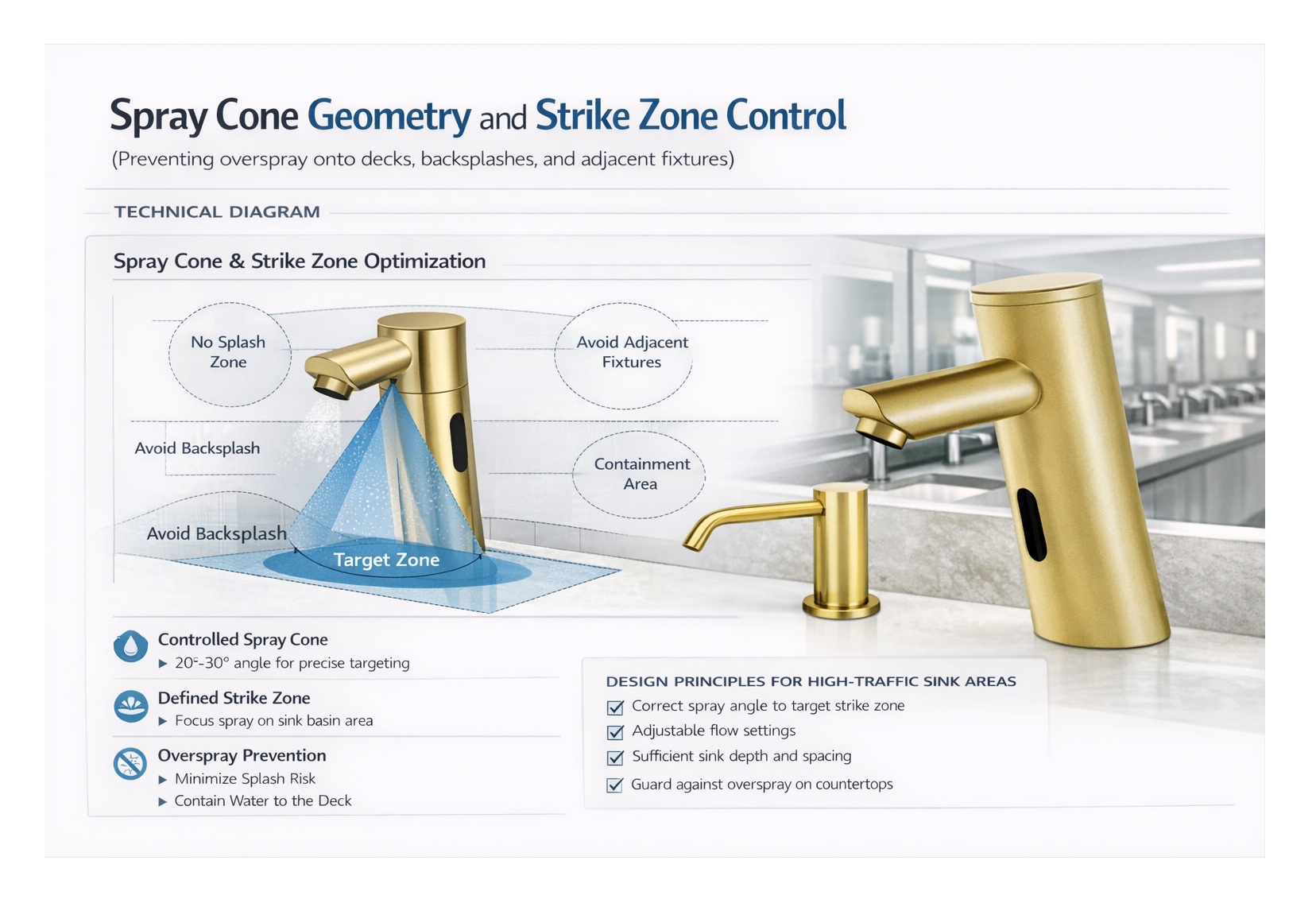

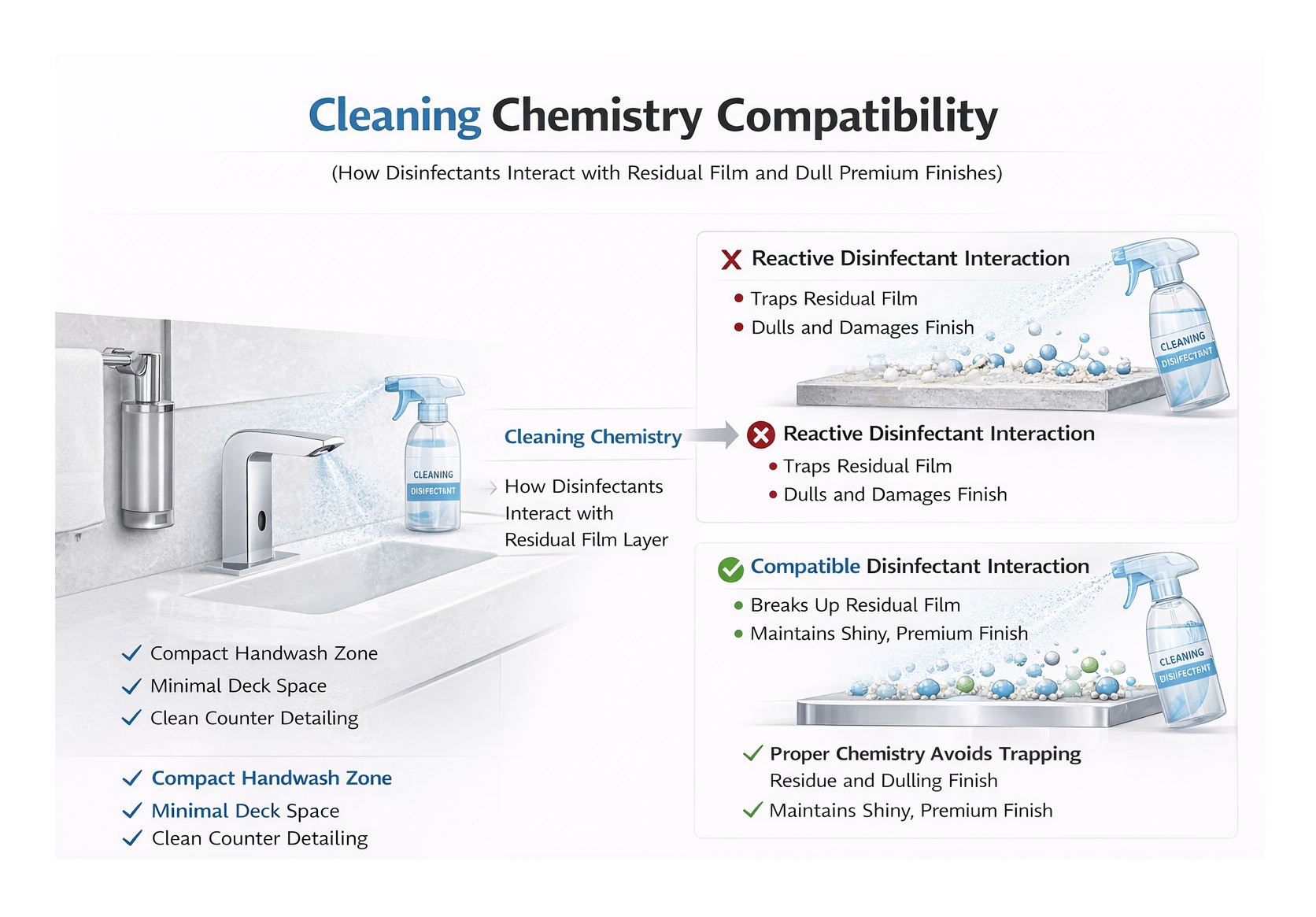

Soap drips can build residue at sink decks, faucet bases, backsplash corners, and seam lines. Mist application can reduce this because the soap arrives on the user’s hand in a thin film instead of falling as a heavy drip-prone volume.

Cleaner counter detailing and fixture appearance

Mist units can support cleaner architectural detailing by lowering residue buildup at perimeter zones where grime tends to accumulate, especially in modern finish programs with minimal seams and thin reveal lines.

How spray and mist dispensing works

Spray units must create atomization rather than pumped flow. Consistent output depends on stable pressure, nozzle geometry, and control logic that avoids sputtering or uneven bursts.

Atomization mechanism

Pump system and fluid path requirements

Sensor control and lockout behavior

Hygiene performance considerations for low-volume dosing

The key question is whether ultra-low volume supports effective hand hygiene behavior. Effectiveness depends on technique, time, and complete coverage, not simply soap volume. Selection should account for formulation compatibility and user experience so the output supports adequate coverage rather than a barely-there dose.

Where spray or mist units fit best

Best-fit environments

Less ideal environments

Specification requirements that matter in commercial projects

Output control and dose repeatability

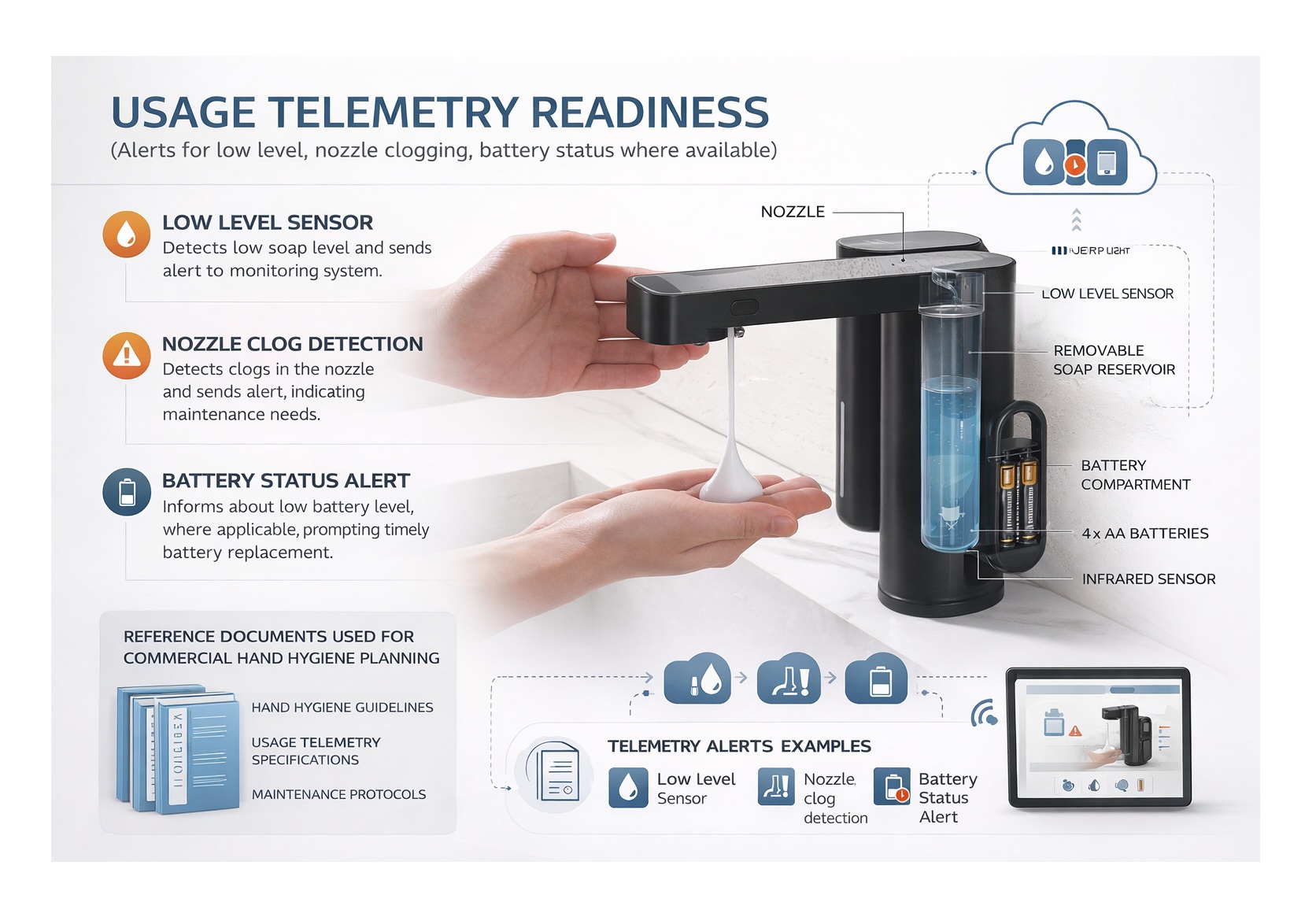

Nozzle performance and clog resistance

Residue and drip control

Activation stability for infrared sensor models

Service access and refill monitoring

Recommended commercial infrared sensor dispenser brands

These brands are commonly specified for commercial infrared sensor dispensing systems and are relevant when selecting sensor logic and controlled dosing designs.

AEC selection checklist

Spray or mist hand hygiene dispenser shall:

Sources and technical references

No responses yet