SoapDispensing | Smart Buildings & Hygiene Infrastructure

Soap dispensers are often specified as “minor accessories,” but in real buildings they behave like mini systems: they have consumables, moving parts, power requirements, failure modes, and a direct impact on tenant experience. At SoapDispensing, the focus is practical dispensing that holds up in workplaces, hospitality, healthcare, and other high-use environments—where reliability and maintainability matter as much as aesthetics.

What’s changed over the last few years is that dispensers (and adjacent hygiene fixtures) can now be data-enabled—reporting refill status, usage events, faults, and service alerts. When done well, this turns restroom support from complaint-driven to predictable operations, and gives AEC teams a clearer path to specify for outcomes instead of guesswork.

What “data-enabled dispensing” actually means (beyond “touchless”)

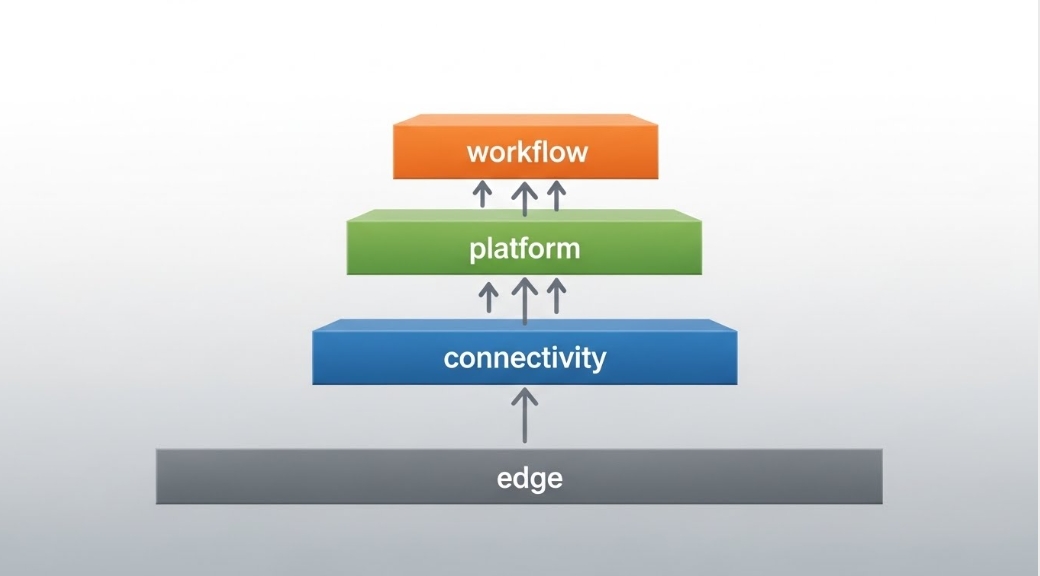

A modern connected dispenser program is typically a stack:

- Edge device: the dispenser (sensor, pump, reservoir/cartridge) + local status/diagnostics

- Connectivity layer: direct Wi-Fi or BLE-to-gateway (varies by manufacturer/site constraints)

- Cloud or local platform: dashboards, analytics, alert rules, and integrations

- Workflow integration: CMMS tickets, mobile tasking, compliance reporting, or portfolio dashboards

In other words: you’re not just buying fixtures—you’re introducing an operational data stream into the building.

The facility case: convert “walk-arounds” into targeted work

In most buildings, soap-related labor isn’t the refill itself—it’s the checking and the repeat call-backs (“empty,” “leaking,” “random dispensing,” “doesn’t work”). Connected platforms aim to reduce that by using supply-level monitoring and alerts so staff act only where needed.

Examples of what commercial platforms explicitly market include:

- Refill-on-demand based on dispenser status/traffic (reducing routine “just in case” checks)

- Real-time data/insights tied to dispensers to track usage and reduce run-outs/waste

- Service alerts and integration options (e.g., working alongside existing RTLS in healthcare settings)

Practical FM KPIs (the ones that change staffing and outcomes)

Track a small set that ties directly to labor and complaints:

- “Empty time” (hours per month dispensers are empty)

- Refill adherence (missed refill events vs planned visits)

- Battery incidents (dead battery events vs planned replacements)

- Fault closure time (alert → work completion time)

- Consumable variance (unexpected overuse that signals leaks, over-dosing, or misuse)

AEC coordination: treat dispensers like a maintainable, connected subsystem

If the building has any smart infrastructure, dispensers should be scoped like other connected devices:

A) Physical integration & service access

- Confirm backing/blocking and anti-tamper needs (wall-mounted)

- Confirm under-counter access (deck-mounted) for refills + battery/service

- Avoid placements that create chronic false triggers (mirrors, reflective backsplashes, direct sunlight)

B) Power strategy (don’t make battery a surprise)

Battery is often the fastest retrofit path, but you need an actual plan for replacement cycles.

For “smart maintenance” programs, validate whether the model family supports reduced battery touch points (where applicable).

C) Connectivity + commissioning

Commissioning must include both dispense performance and data performance:

- Prime and validate consistent dose (10 cycles)

- Validate sensor activation zone and shutoff behavior

- Validate reporting (online status, low-soap trigger, low-battery trigger, fault reporting)

- Validate workflow output (ticket creation / service alert / dashboard update)

Integrations that actually matter: CMMS first, dashboards second

Most facilities realize the value only when alerts drive action. The most common, high-impact pattern:

Dispenser alert → CMMS work order → technician completes task → closure timestamp feeds KPI reporting

This requires a basic data contract:

- Asset ID

- Exact location (building/floor/restroom bank)

- Alert type + severity

- Last-known level / battery / fault code

- Timestamp and SLA target

Some platforms explicitly note the ability to integrate data into your own reporting/IT systems (e.g., via API offerings).

Cybersecurity and data governance: baseline expectations (AEC + owner rep)

Even “simple” IoT devices deserve a minimum baseline review because they live on your network and generate operational data. A practical approach is to map device and vendor capabilities to a recognized baseline such as NISTIR 8259A (IoT device cybersecurity capability core baseline).

For project delivery, include these in submittals / closeout:

- How device identity is handled (unique IDs, credentialing approach)

- Firmware update mechanism and support period

- Data collected (events/levels), retention, and access controls

- Network requirements (outbound domains/ports) and segmentation expectations

Closeout deliverables: what to request so operations doesn’t “inherit mystery systems”

For each dispenser family in the connected program:

- Cut sheets + installation/maintenance manuals

- Power plan (battery cadence or wiring/transformer details)

- Asset tagging plan (location + model + power type + connectivity)

- Commissioning record (dispense + alert verification)

- Integration notes (what triggers tickets/alerts, and how closures are recorded)

This is the difference between a “smart restroom” and an expensive pilot no one can maintain.

Support documents (downloadable)

Verified source links (clean URLs, no tracking params)

Connected hygiene / smart servicing examples and security baselines

No responses yet