Automatic soap dispensers have become standard fixtures in many health care, transport and hospitality projects. For architects and engineers, these devices are not only hardware on a wall or counter. They are sensor driven systems that affect user safety, hygiene performance, power distribution and coordination in digital models. Sensor choice influences false activation rates, response time, basin geometry, and even long term maintenance costs.

This article provides a technical overview of the main sensing approaches used in automatic soap dispensing systems, with a focus on infrared sensing, Time of Flight sensing and capacitive sensing. It relates these technologies to commercial products from FontanaShowers and BathSelect and to the information that design teams need for specification and BIM content.

1. Why sensor selection matters in AEC projects

In an architectural context, the sensor system inside a dispenser affects more than user experience. It has direct impact on

- Water and soap consumption

- How closely dispensers can be placed near bright daylight, stainless steel or reflective basins

- Accessibility and reach ranges

- Electrical and low voltage design

- Maintenance access and replacement cycles

Manufacturers such as FontanaShowers supply complete assemblies that pair touchless faucets and soap dispensers for public restrooms, for example the commercial sets presented in the product overview for automatic sensor faucet and soap dispenser combinations. BathSelect positions similar equipment for hotels and mixed use projects through its BathSelect hospitality touchless bathroom faucet and soap dispenser program. In both cases, sensor performance is central to the value of the system.

2. Infrared sensing in automatic soap dispensers

Infrared sensing is the most common approach in commercial soap dispensers. A typical system uses an emitter that sends out infrared light and a receiver that measures the reflected signal. When a hand enters the detection zone, the returned energy changes. The control board interprets this change as a demand for soap.

A clear explanation of this principle appears in the article What is automatic soap dispenser and how does it work, which describes the role of passive infrared sensing in wall mounted and deck mounted dispensers. More detailed design notes are available in the Holtek touch automatic soap dispenser reference design, which shows how an infrared transceiver is combined with a microcontroller that manages gain, signal filtering and motor drive.

For architects, the main points to carry into the specification and BIM model are

- Infrared sensors can be sensitive to strong sunlight, specular reflections and steam

- The effective sensing range may change when basin color or shape changes

- Mirror proximity and high gloss splashbacks can increase false triggers if clearances are tight

The model family should allow editing of the nominal sensing distance, so that designers can coordinate vertical placement and basin offsets.

3. Time of Flight sensing for greater stability

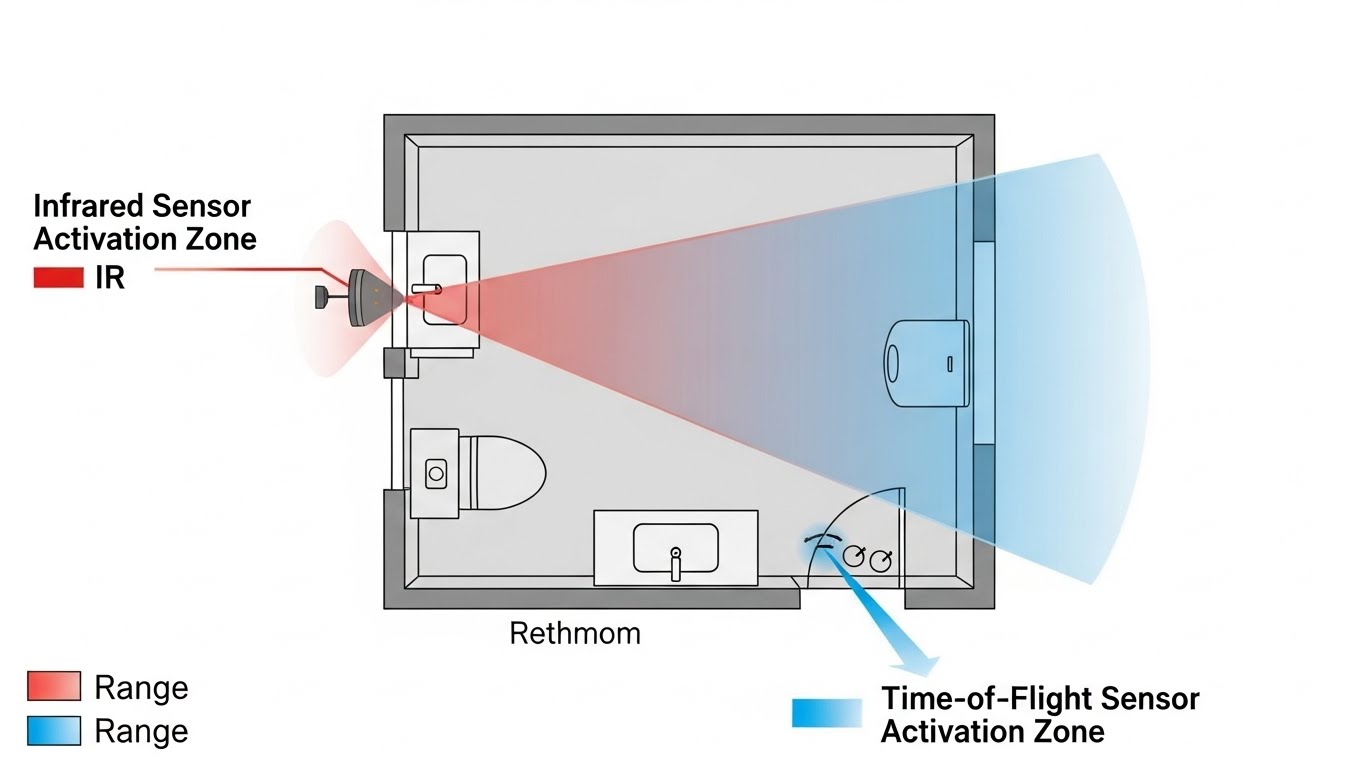

Time of Flight sensing represents a newer approach for touchless sanitary equipment. Rather than relying on the intensity of reflected light, a Time of Flight sensor measures the travel time of a modulated infrared signal between emitter, target and receiver. The system converts this into an absolute distance.

FontanaShowers published an article providing an overview of its ToF sensor technology for touchless faucets and soap dispensers. The article explains that Time of Flight sensing provides more reliable detection in varying lighting conditions and compact spaces than traditional intensity-based infrared sensors do.

Key implications for design teams include

- A better-defined activation zone, which helps when basins are shallow or very close together

- Reduced sensitivity to bright ambient light and reflections from stainless steel or mirrors

- The ability to tune distance based activation in the field without major hardware changes

For projects that involve airports, rail stations or large health care facilities, where equipment runs continuously and maintenance windows are short, the additional stability of Time of Flight systems can justify a higher initial device cost.

4. Capacitive sensing in soap dispensing systems

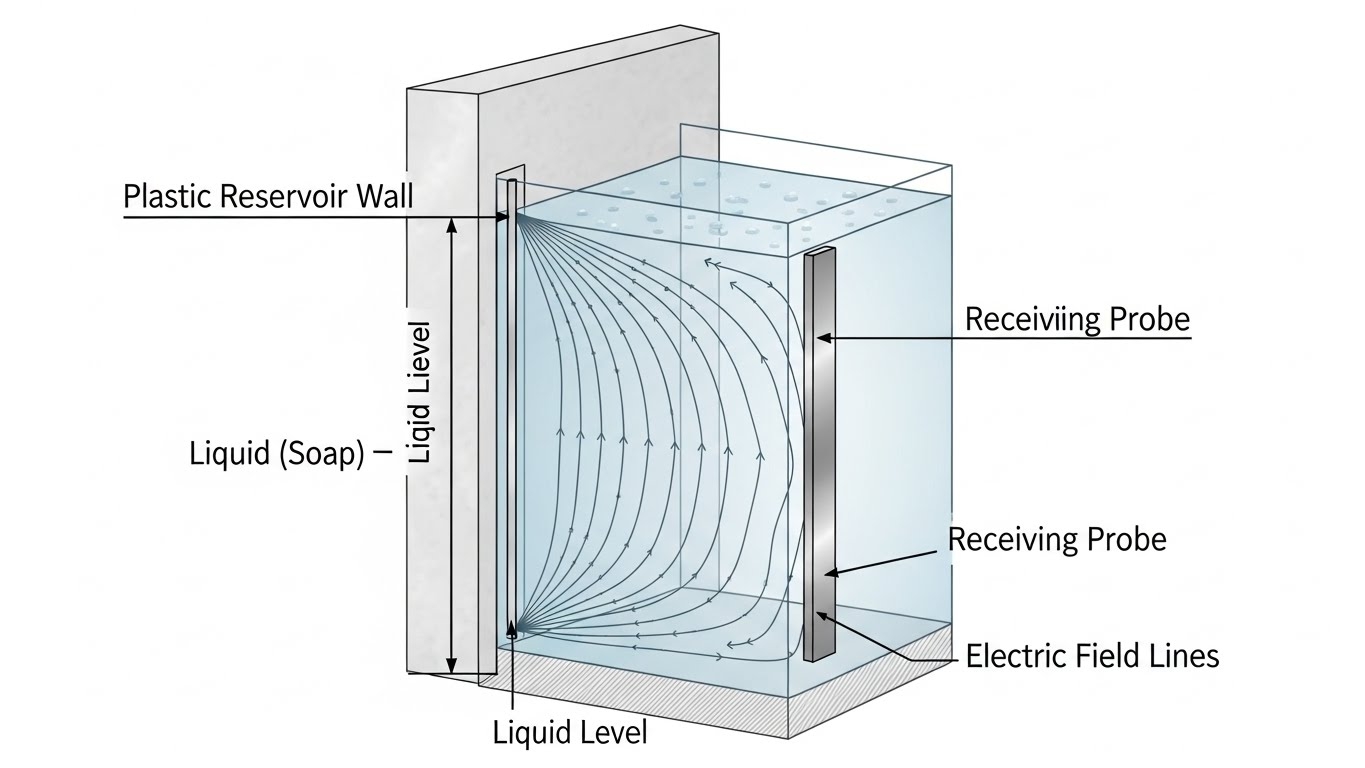

Capacitive sensing plays two main roles in dispenser systems. First, it can replace or supplement infrared based user detection. Second, it can monitor liquid level inside the soap reservoir.

A capacitive proximity sensor measures changes in the electric field around a sensing face. It can detect the presence of conductive or dielectric materials, such as human hands, plastics, and liquids. Technical summaries from sensor vendors describe how these devices support noncontact detection across a range of materials. For example, there is an introduction to capacitive proximity sensors for liquid level and plastic detection.

In level detection applications, the sensor measures the change in capacitance as the soap level rises or falls near the probe. Omron and Baumer publish examples, such as the Omron E2K L capacitive liquid level sensor and the Baumer capacitive level sensor portfolio, which both work through plastic walls without direct contact with the medium. Texas Instruments adds circuit level detail in the capacitive based liquid level sensing reference design, which introduces techniques to filter out interference from nearby hands.

In commercial soap systems, capacitive sensing can support

- More accurate detection of a user in very small basins, sometimes in combination with infrared

- Monitoring of soap level to trigger status signals for maintenance staff

- Improved resistance to steam and aerosol around heavily used wash zones

For BIM, capacitive based dispensers should carry parameters that indicate whether telemetry is available for soap level and whether the signal can integrate with a building management system.

5. Sensor technology in FontanaShowers and BathSelect solutions

Many commercial product lines use a mix of these sensing methods. FontanaShowers combines infrared sensing with Time of Flight sensing in some of its premium fixtures, including the dual faucet and dispenser assemblies promoted in the Fontana dual function automatic sensor faucet and soap dispenser series on ArchDaily. A more specification focused view of similar equipment appears in the Fontana automatic sensor faucet and soap dispenser data sheet.

BathSelect highlights its commercial focus and sensor driven hygiene benefits across the BathSelect hospitality touchless bathroom faucet and automatic soap dispenser range. The product descriptions stress controlled dosing, fast response and compatibility with different soaps, all of which depend on consistent sensor behaviour.

When incorporating these products into a project, design teams should treat the sensor block as a defined component within the BIM family, with parameters for detection range, recommended mounting height and any environmental limits.

6. Design, commissioning and maintenance considerations

Sensor selection influences early design decisions and ongoing maintenance. Infrared based systems require more attention to finishes. Designers should consider basin color, mirror framing, lighting location and the presence of strong daylight in the activation zone. The time-of-flight systems mitigate these sensitivities yet still need unobstructed views. The capacitive systems need to be imposed carefully and also the presence of metalwork around the areabneed to be taken into consideration to avoid any interference.

Commissioning teams should verify sensing performance in the actual lighting and reflection environment, not only under factory default settings. Video resources such as the explanatory film How automatic soap dispensers detect a hand can help maintenance staff understand what the sensors are doing and why small changes in geometry can matter.

Maintenance planning also changes with sensor type. Time of Flight and capacitive sensors can reduce false activations, which in turn reduces soap waste and the frequency of refills. Systems with capacitive level sensing can report low soap status, which supports planned rather than reactive maintenance, especially when combined with telemetry and dashboards.

7. Specification and BIM checklist

When drafting specifications and assembling BIM content for soap dispensing systems, architects can use the following checklist.

Specify for each dispenser family

- Sensor type infrared, Time of Flight, capacitive or hybrid

- Nominal detection range and mounting height limits

- Environmental constraints such as strong sunlight, steam or high reflectance finishes

- Availability of telemetry for usage count and liquid level

- Power requirements and low voltage transformer locations

- Compatibility with coordinated touchless faucet ranges such as the Fontana automatic sensor faucet and soap dispenser combinations.

Within the model, store links to the manufacturer technical pages, for example the Fontana ToF sensor technology overview and the BathSelect hospitality touchless faucet and dispenser collection, so that future team members can reach current documentation easily.

8. Conclusion

Infrared, Time of Flight and capacitive sensing each bring distinct strengths to automatic soap dispensing systems used in contemporary projects. Infrared remains familiar and widely available. Time of Flight offers stable distance based activation in compact and visually complex restrooms. Capacitive sensing adds new options for both user detection and liquid level monitoring.

For AEC professionals, sensor technology is not a hidden internal detail. It shapes user experience, influences layout rules and supports digital building management. By referencing manufacturing resources such as the Fontana ToF sensor technology article, along with independent sensor design notes and level sensing references, a design team can choose and document soap dispensing systems that match both the design intent and long-term operational needs.

No responses yet