Automatic and touchless soap dispensers have become core infection-control infrastructure in contemporary commercial buildings. For architects, engineers, and construction professionals, the specification of sensor-based dispensing systems is now driven by quantifiable impacts on hygiene performance, user safety, and lifecycle cost. This article reviews current research on hand hygiene outcomes, compares manual and automatic systems, and translates key findings into specification guidance for healthcare, hospitality, education, transportation, and office environments.

1. Evidence Base: Hand Hygiene Outcomes and Compliance

The clinical and operational justification for automatic dispensers is grounded in public health guidance and peer-reviewed studies. The World Health Organization Guidelines on Hand Hygiene in Health Care consolidate extensive evidence showing that appropriately implemented hand hygiene programs reduce healthcare-associated infections and provide detailed recommendations for system design and monitoring.

The CDC Handwashing Facts for Clean Hands highlight that many diseases and conditions are spread by inadequate handwashing, and that its recommendations for handwashing and hand sanitiser use are derived from multiple controlled studies rather than opinion.

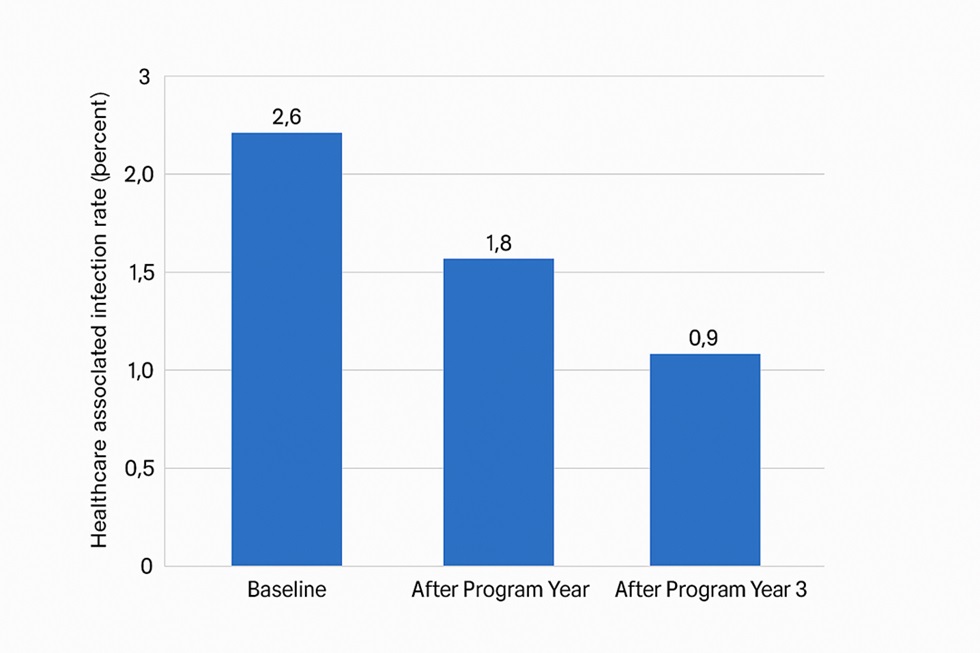

Implementation research demonstrates that structured hand hygiene programs can reduce hospital infection rates from values above two percent to below one percent over several years, with a strong negative correlation between improved compliance and infection incidence. For AEC professionals, the implication is that fixture selection and layout directly influence the ability of operators to reach target compliance levels and thereby affect infection outcomes and regulatory risk.

2. Manual versus Automatic Soap Dispensers

2.1 Comparative performance

Studies comparing manual pump dispensers with touch-free units in patient rooms and clinical corridors have found that overall soap consumption can be similar when placement and capacity are equivalent. However, automatic systems provide additional benefits by removing a frequently touched surface and by delivering accurate, repeatable doses.

Technical and industry reports show that well-designed automatic dispensers maintain consistent shot volumes, minimise dripping, and avoid the need for users to contact push bars or pump heads that may harbour pathogens. This directly supports both infection-prevention objectives and operational predictability for product consumption.

2.2 Compliance and behaviour

Global summaries such as the WHO hand hygiene guidance for healthcare document that baseline compliance among healthcare workers often remains well below full adherence even in high-profile institutions. Interventions that combine improved dispenser placement, touch-free operation, education, and feedback mechanisms have been associated with substantial increases in compliance and measurable reductions in infection rates.

From an AEC standpoint, these findings support a design approach in which automatic dispensers are treated as engineered controls that must be coordinated with circulation, clinical processes, and ergonomics, rather than as decorative accessories.

3. Cost, Lifecycle, and Business Case

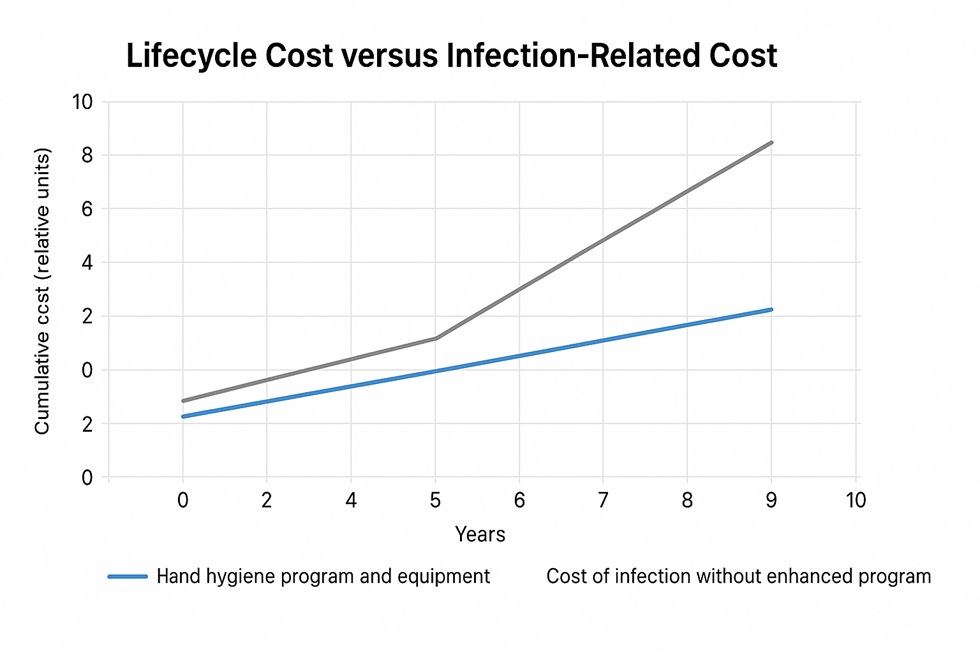

Hand hygiene programs incur recurring expenses for soap and equipment, but the excess cost of even a small number of avoidable infections can exceed an entire annual hand hygiene budget for an inpatient unit. CDC-aligned economic analyses and case examples referenced in CDC clean-hands resources emphasise that investment in robust hand hygiene infrastructure is financially justified when viewed against the cost of additional bed days and treatment.

Automatic soap dispensers contribute to a favourable lifecycle profile through:

- Controlled dosing – Factory-set or adjustable volumetric shots reduce overuse and provide predictable consumption profiles.

- Waste reduction – Responsive sensing and clean cut-off characteristics limit pooling of unused soap on counter surfaces.

- Durable construction – Commercial-grade brass or stainless steel bodies, hardened finishes, and sealed electronics are designed for high-cycle environments and extended service life.

When total cost of ownership is evaluated across the service life of a high-traffic washroom, especially in healthcare, education, airport, or stadium applications, automatic dispensers usually support a strong business case once infection prevention and reduced maintenance are considered.

4. Technical Parameters for AEC Specifications

4.1 Dose accuracy and product compatibility

Engineering evaluations of modern dispensing mechanisms demonstrate that high-quality automatic units can maintain tight control of dose volume with modest variance, supporting both hygiene targets and budget planning.

Technical sections should address:

- Nominal shot volume and allowable variance for the selected soap type

- Adjustability range to align with the organisation’s hand hygiene protocol

- Acceptable viscosity range for liquid or foam soaps, including antimicrobial formulations

This ensures that the dispenser will deliver consistent performance with the specified soap across the facility.

4.2 Sensor performance and user experience

Infrared sensor technology is widely used in commercial automatic dispensers. Specifications should require:

- Stable detection over the defined sensor range

- Short response time from hand presentation to discharge

- Reliable cut-off to prevent trailing and dripping

Evidence from field deployments of commercial wall-mounted automatic soap dispensers and similar units indicates that poor sensor tuning and low-quality electronics are leading causes of user dissatisfaction and maintenance calls. Systems tested for high activation counts and robust electromagnetic compatibility are preferable in complex building environments.

4.3 Construction, finishes, and vandal resistance

In transportation hubs, education campuses, and other public venues, fixtures must tolerate both heavy usage and occasional abuse. Many FontanaShowers commercial automatic soap dispenser models use solid brass or stainless steel bodies with commercial-grade finishes and vandal-resistant construction, making them suitable for environments with heavy use.

To maintain a unified design language, specifiers commonly coordinate these with FontanaShowers touchless sensor faucets for public restrooms, selecting harmonised finishes such as satin nickel, brushed gold, matte black, or architectural chrome to align with the project’s metalwork and hardware palette.

5. Placement, Standards, and System Integration

5.1 Location strategy and international guidance

The WHO hand hygiene guidelines and CDC handwashing guidance stress that hand hygiene facilities must be readily accessible at points of care and at key movement transitions. In commercial restrooms, this translates into:

- Clear sight lines from the corridor or lobby approach into the basin zone

- Logical alignment of faucet, soap dispenser, and hand-drying system

- Avoidance of cross-traffic that forces users to reach across others to access soap

A coordinated layout reduces the number of steps and touchpoints in the handwashing sequence, supporting throughput, accessibility, and compliance.

5.2 Alignment with green and wellness goals

Green building and wellness certification systems increasingly recognise infection-control strategies as part of occupant health. While specific criteria vary, touchless fixtures can be referenced in design narratives that describe how the building supports reduced disease transmission, improved perception of cleanliness, and resilient operation during seasonal or regional outbreaks. Combining automatic dispensers with water-efficient spec-grade touchless faucets and soap dispensers can also support water-use performance goals.

5.3 Power, controls, and monitoring

Most contemporary commercial dispensers offer battery, low-voltage, or hybrid power options. For large venues and multi-site portfolios, owners are beginning to request integration with smart restroom platforms or building-management systems, enabling remote monitoring of product levels, activation counts, and fault conditions. Product families such as the BathSelect commercial automatic brushed nickel liquid foam soap dispenser and related deck-mounted models provide adjustable timing, dosing, and energy-efficient operation appropriate for such environments.

6. Brand and Product Families for Project-Scale Deployment

Standardizing on a small number of coordinated product families makes it easier for clients who manage multiple facilities to buy, train, and maintain them while making sure they all work the same way.

- FontanaShowers – FontanaShowers commercial automatic soap dispenser range includes wall- and deck-mounted sensor dispensers configured for high-traffic restrooms. They pair well with the touchless bathroom faucet collection, which offers proximity-activated faucets suitable for ADA-conscious and spec-grade applications. The page on how to specify Fontana touchless faucets and soap dispensers in bid documents provides design teams developing project manuals with Division 22 and Division 10 sample language, BIM links, and coordination checklists.

- BathSelect – The BathSelect Hospitality Collection offers commercial touchless bathroom faucets and automatic soap dispensers for hotels, mixed-use developments, and public restrooms. These products feature coordinated faucet and dispenser assemblies. Models such as the gold automatic deck-mounted foam soap dispenser and the dual-function deck-mount faucet and soap dispenser offer finish options and performance features suitable for premium hospitality and corporate projects.

Reliance on manufacturer-provided BIM objects, cut sheets, and technical hubs, such as Fontana’s touchless technical resources for faucet systems, helps ensure accurate coordination across architecture, interiors, and MEP disciplines in each case.

7. Practical Specification Checklist for AEC Teams

The following checklist, based on the research and product data summarized above, can support project documentation and coordination.

- Performance and dosing

- Define a target dose volume and allowable variance for the selected soap and confirm compatibility with the product’s viscosity range, using technical information from manufacturers and from dedicated hubs such as the technicals for touchless faucets and soap dispensers.

- Hygiene and user experience

- Require touch-free infrared sensing with rapid response and stable detection over the installed range.

- Coordinate faucet, dispenser, and dryer locations in accordance with WHO hand hygiene guidance and CDC handwashing recommendations to minimise movement and potential recontamination.

- Lifecycle and cost

- Document expected product consumption and maintenance intervals for high-traffic conditions using manufacturer data and field experience.

- Relate program costs to the economic burden of preventable infections, drawing on statistics from CDC clean-hands data and research.

- Integration and maintainability

- Specify power strategy, access clearances, and any required conduits or raceways, referencing spec-grade resources such as the Fontana spec-grade touchless faucets, dispensers, and showers collection.

- Where appropriate, include options for telemetry, remote monitoring, and alerting as part of smart restroom or building-management system integration.

Conclusion

Automatic soap dispensers in commercial settings are now supported by a substantial body of evidence that links improved hand hygiene to reduced infection rates and favourable lifecycle economics. Guidance from the World Health Organization and the CDC clean-hands program confirms that fixture design and placement are integral components of effective hand hygiene systems.

For AEC professionals, soap dispensing systems should be treated as critical elements of health-focused building infrastructure. By incorporating evidence-based performance criteria, coordinating layouts with international guidance, and standardising on proven product families from manufacturers such as FontanaShowers and BathSelect Hospitality, project teams can deliver washrooms and clinical spaces that support occupant safety, operational resilience, and long-term value.

No responses yet